rockwell hardness test on 4140 stee|4140 temper chart : discount store Grade 4140 is a Chromium-Molybdenum through-hardening steel of medium hardenability. It is a general-purpose high-tensile steel with medium strength level and good . Create and get +5 IQ. [Chorus] A E Quando eu cheguei aqui meu Senhor já estava D E A Quando eu cheguei aqui meu Senhor já estava E No meio da igreja ele passeava D E .

{plog:ftitle_list}

web29 de ago. de 2023 · Neste artigo, vamos abordar um tema bastante polêmico e muito buscado na internet: como clonar um celular grátis. Sabemos que o assunto envolve questões legais e éticas, mas entendemos que existem situações em que é necessário monitorar ou acompanhar de perto o celular de outra pessoa.

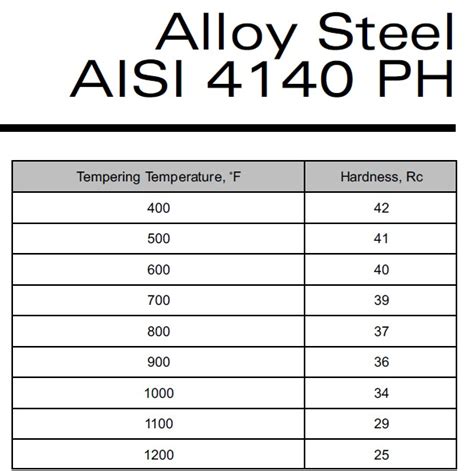

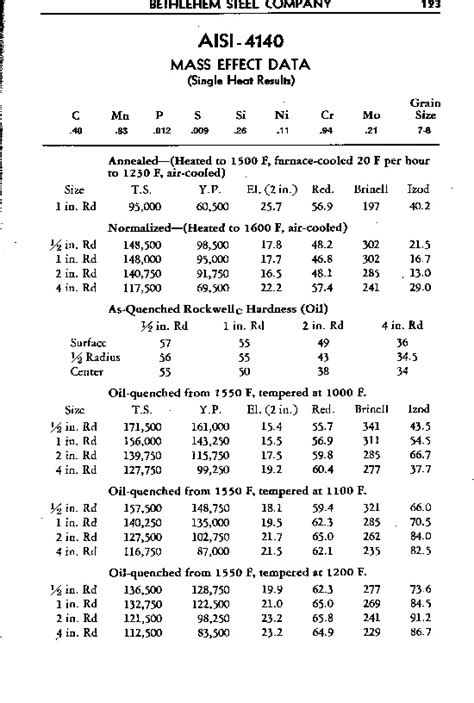

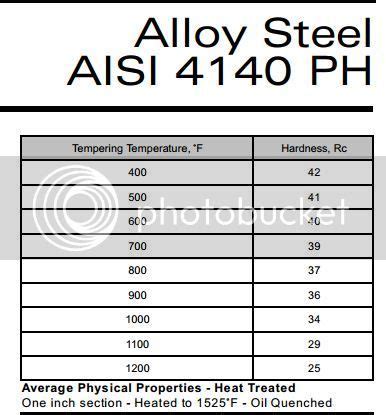

Tempering temperature of 4140 alloy steel can be from 204-649 °C (400-1200°F) after normalizing and oil quenching, and the corresponding Rockwell hardness can be obtained. Forging. Material 4140 forging temperature is about 1232 °C (2250 °F). Welding of 4140 Steel

EN10025 S355JR Steel (1.0045 Material) S355JR steel (1.0045 material) is one of .Alloy Steel Grade 4140 Fact Sheet. AISI 4140 Steel, normalized at 870°C (1600°F), air cooled, 25 mm (1 in.) round. Subcategories: Alloy Steel; AISI 4000 Series Steel; Low Alloy Steel; Carbon . Grade 4140 is a Chromium-Molybdenum through-hardening steel of medium hardenability. It is a general-purpose high-tensile steel with medium strength level and good . AISI 4140 steel typically boasts a prehard hardness ranging from 28 to 32 HRC (Rockwell Hardness Scale C). This inherent hardness makes it an attractive choice for .

3.Rockwell Hardness Test: This method is a metal hardness test method represented by the HRC symbol, which measures the depth or union depth and rebound depth of the indentation formed on the surface of 4140 steel, and . The hardness of 4140 Alloy Steel is a very important mechanical attribute that affects its performance in numerous applications. Normally, in the annealed state, this alloy .

AISI 4140 alloy steel is a chromium-, molybdenum-, and manganese-containing low alloy steel. It has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength. The following datasheet .AISI 4140 chrome-molybdenum steel can be oil hardened to a relatively high level of hardness. The desirable properties of the AISI 4140 include superior toughness, good ductility and good .

Overview. This alloy has high strength, high fatigue strength, toughness, torsional strength, and impact and abrasion resistance.

One of the standout features of 4140 annealed steel is its exceptional hardness. It ranks high on the Rockwell hardness scale, making it a preferred choice for applications where hardness is a critical factor. In this article, we will explore the 4140 steel heat treatment methods, heat treatment temperature & cycles benefits, and applications. Understanding 4140 Steel. 4140 steel is a versatile low-alloy steel that . Grade 4140 is supplied in the hardened and tempered condition. The level of hardness is selected to give useful strength while still maintaining the ability to machine the material into finished components. Diameter (mm) Heat Treated Condition Tensile Strength (MPa) 0.2% Proof Stress (MPa) Elongation (% in 50mm) Impact Izod or Charpy Hardness

of the steel, such as strength, toughness, and wear resistance. Also referred to as SAE 4140, this steel grade has high hardenability, which means it can be heat treated to achieve high strength and hardness levels. AISI 4140 steel is a popular low-alloy steel that contains chromium, molybdenum, and manganese as alloying elements. AISI 4140Learn important details about alloy-steel 4140 and other metals using the OnlineMetals.com® Product Guide. . Mill Test Reports. Products. 4140 Sheet/Plate | 4140 Round Bar | Round Tube . 0.283 lb/in3: Ultimate Tensile Strength: 95 ksi: Yield Tensile Strength: 60.2 ksi: Shear Strength: 69 ksi: Hardness Rockwell | Brinell: B92 | 197 . The hardness of 4140 Alloy Steel is a very important mechanical attribute that affects its performance in numerous applications. . (Rockwell Hardness Scale C). Nevertheless, by tempering after quenching or other heat treatment methods it can be made harder – up to about 54 HRC depending on parameters used. . (American Society for Testing . Hardness of 4140 steel at different temperatures. Hardness is another key mechanical property of 4140 steel affected by temperature. Typical hardness of 4140 steel is about 28-32 HRC(Rockwell C scale) at room temperature. However, as the temperature increases, the hardness of the steel decreases. At 200°C the hardness drops to about 25-28 .

This term refers to the hardness level exhibited by the steel before undergoing any heat treatment. AISI 4140 steel typically boasts a prehard hardness ranging from 28 to 32 HRC (Rockwell Hardness Scale C). This inherent hardness makes it an attractive choice for numerous applications where strength and durability are paramount. We're doing a hardness test, Rockwell C, on 2" OD x 1" ID tube of SAE 4140 steel that is supposed to be hardened and tempered to a 32-36 hardness. We are seeing a different hardness on the outside vs. inside, almost like the steel has a "skin". Once we get ~ .025" or more under the "skin" we.A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters. This process is crucial in achieving the desired properties of 4140 annealed steel. Mechanical Properties 3. Hardness. One of the standout features of 4140 annealed steel is its exceptional hardness. It ranks high on the Rockwell hardness scale, making it a preferred choice for applications where hardness is a critical factor. 4. Tensile Strength

The Rockwell C test uses a diamond cone indenter with a minor 10 kg then major 150 kg load. Penetration depth difference determines hardness level. For 4140 steel, 22 to 30 HRC is typical, depending on heat treatment. This .The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on . Steel/Iron Light Metal Copper Aluminium Light Metal Copper Aluminium Light Metal Light Metal Lead/Tin *Recommended hardness range according to EN ISO 6506-4 .

pretested for machinability through Niagara LaSalle’s unique testing procedure. 1/2 0.6708.04 9/16 0.850 10.20 5/8 1.04012.48 . Rockwell C Hardness ... **32 (Min) Brinell Hardness ... **302 (Min) . *Applies only to 4140 leaded alloy steel bars.In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. . A high Rockwell number indicates high steel. Hard materials on the .The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the . The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.

3) Tempering recommendations from the ASM heat treaters guide for 4140-4142 is a minimum of 400°F. This leaves near full hardness. The following table is extrapolated from a hardness graph given in Brinell Hardness with nearest points taken from a conversion table for Rockwell hardness. Tensile values are generic, not specifically for 4140.

4140 tensile strength chart

Annealed 4140 Steel, 4140 ann, cut pieces or full length bars (up to 24 Feet). Phone: 800.321.9300. Request a Quote. . ASC2250® LDX Caustic Solution Corrosion Testing Data; ASC2250® LDX General Corrosion Resistance Data; . It is offered in the cold finished annealed condition. Typical hardness is Rockwell “C” 19/24. This blog will delve into a comprehensive comparison of 4140 steel hardness with other steel grades, providing insights that will help engineers, metallurgists, and manufacturers make informed decisions about material selection. . The most common methods include the Rockwell Hardness Test, Brinell Hardness Test, and Vickers Hardness Test .

The fatigue test data for 4140 Quenched and Tempered steel (iteration 66) obtained in this investigation are given in Table 1. The stress amplitude corresponding to each strain amplitude was calculated from the peak load amplitude at the specimen half-life. A fatigue strain life curve for the 4140 Quenched and Tempered steel is shown in Figure Here are some ways to test 4140 steel for quality and performance: Hardness Test. The Rockwell hardness test is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indent into the surface of a material. During the test, a metal component or metal .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).

What Rockwell hardness value do you wish on your finished part? Is there a reason you are using pre-hardened 4140 or 4130? Another tool steel may be a better choice for your desired result. . Rockwell Hardness Testing - HRc vs N scale rwa2004; May 24, 2024; Metrology; Replies 13 Views 665. May 31, 2024. winger. W. W.

Steel Bar 4140 Colour code: Jade (Band) – Bluebell Introduction Atlas 4140 is a Chromium-Molybdenum through-hardening steel of medium hardenability. . Rockwell hardness (HRC) max min Possible Alternative Grades Grade Why it .AISI 410 stainless steel mechanical properties are given in the datasheet below including tensile strength, yield strength, elongation, reduction in area, Brinell and Rockwell hardness, charpy impact test, etc. Datasheet 3, Type 410 stainless steel properties – 2.Impact Factor (JCC): 7.6197 SCOPUS Indexed Journal NAAS Rating: 3.11 Effect of Heat Treatment and Mechanical Characterization of AISI 4140 Steel 607 Table 3: Rockwell Hardness Test Results of as Bought, as well as, Heat Treated Specimens of AISI 4140 Steel Minor Load (Kg) 10 Type of Heat Treatment Specimens Trial 1 As Bought C24 Annealed C9 . Because of its low force, high speed, and nondestructive nature, Rockwell hardness testing commonly is used on all sizes of tubing. To perform a Rockwell test successfully, you must consider several factors. Surface Finish. The surface finish for Rockwell testing must be smooth and uniform to obtain an accurate measurement. If you recognize the .

vac-v1 gas permeability tester

A new music service with official albums, singles, videos, remixes, live performances and more for Android, iOS and desktop.

rockwell hardness test on 4140 stee|4140 temper chart